The Tool Room

Ever wanted to make a custom part for your model? Or perhaps you have an idea as a modification or upgrade but dont have a laser cutter, lathe or milling machine to do the job.

We can help.

Call us on 01633 682795 or us with your ideas and let us know how we can help you.

Here are a few things we have been doing recently.

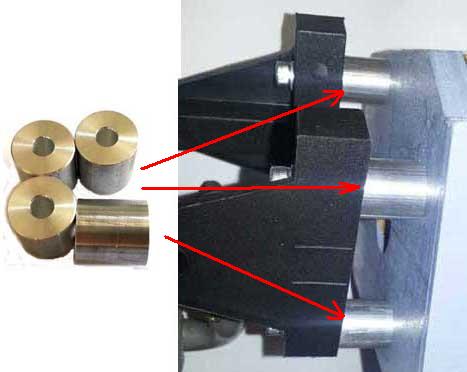

Simple Spacers

It can be just a simple spacer that you need, to push the engine mount out further from the bulk head. In this example the customer requested 15mm diameter x 15mm thick with a 5.1mm hole. He then used M5 x 35mm Cap Head bolts which screwed into M5 blind nuts at the rear of the bulk head.

Olio

We were asked to produce an olio recently as the customer couldnt find the exact size he required. This had a spring inside, enclosed slot with a small machine screw for securing and limiting but still allowing the desired amount of travel.

He specifically requested two grub screws at the top of the olio for mounting.

Throttle Extension

In this instance the throttle arm on the OS 200 Surpass had no clear path to trace a throttle cable so an extension was created to move the arm clear of the engine mount.

There is a 3.1mm hole through the centre of the unit to accept the M3 bolt for fastening, at the carburettor end it was milled out 6.5mm to produce a flat bottom hole to accept the OS throttle body, then at the end that accepts the throttle arm the shank was turned down so it fitted the metal arm and a small flat was milled so the grub screw could locate and fasten the arm to the extension.